Jig and Fixture Services

In the world of industrial manufacturing, there are tools that play a key role in enhancing the accuracy, speed, and quality of production processes. Two prominent examples of these tools are jigs and fixtures, each with their specific functions and applications.

Definition of Jig and Fixture

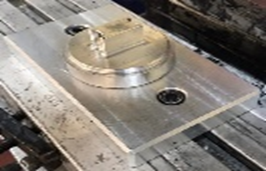

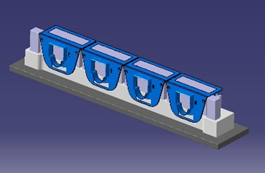

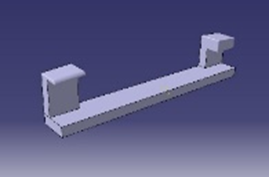

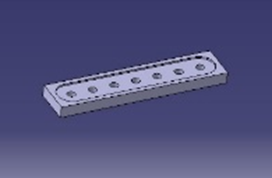

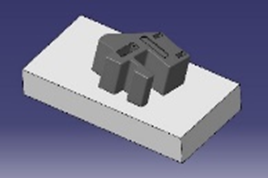

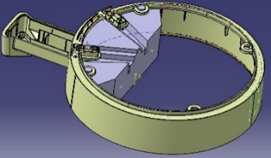

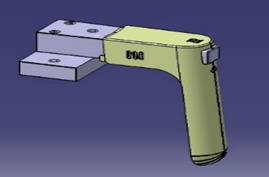

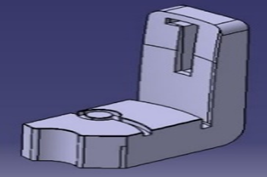

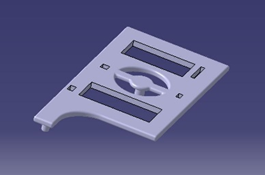

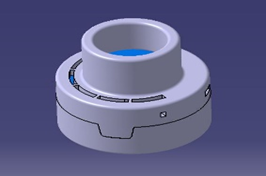

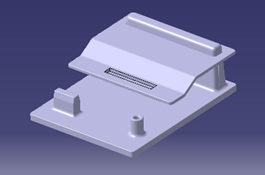

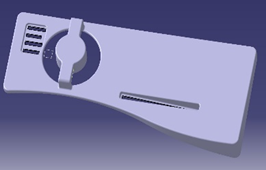

A jig is a tool used to guide and control cutting tools such as drills to perform operations like drilling with high precision. For instance, in the drilling process, a jig guides the drill to precise positions, ensuring that holes are created in the desired locations.

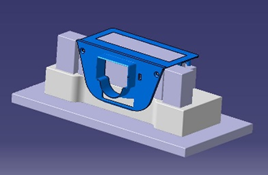

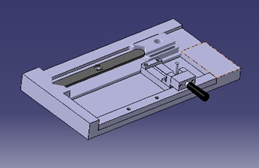

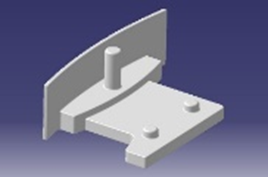

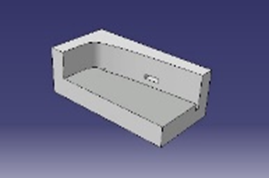

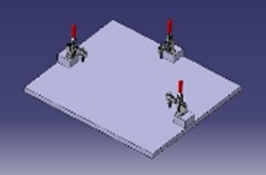

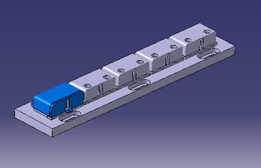

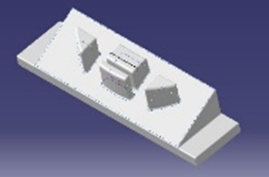

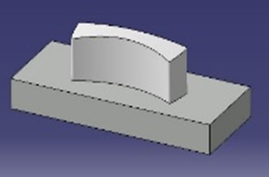

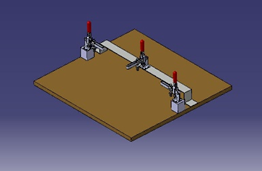

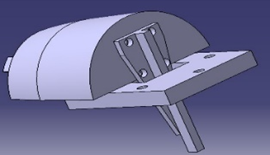

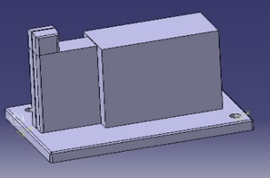

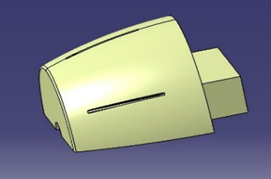

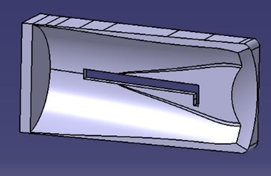

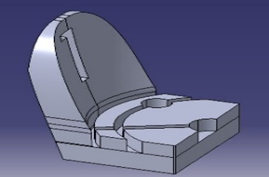

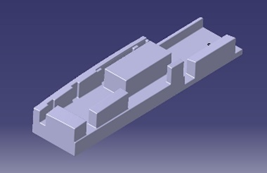

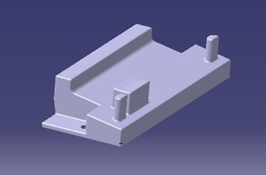

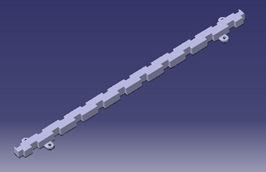

A fixture is a tool that holds the workpiece in a specific position and orientation to perform machining or assembly operations with greater stability and accuracy. For example, in welding processes, fixtures hold parts in place to ensure that welds are performed with high quality and precision.

Key Differences Between Jig and Fixture

The main difference between jigs and fixtures lies in their roles in the production process. Jigs guide cutting tools and are usually lighter and portable, while fixtures hold the workpiece steady and are typically heavier and attached to machinery.

Types of Jigs

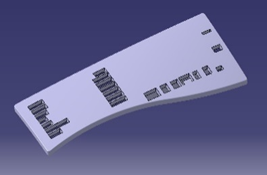

Jigs are categorized based on their application and production needs:

Drilling Jigs: Used to guide drills in drilling operations.

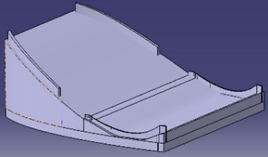

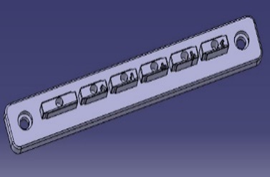

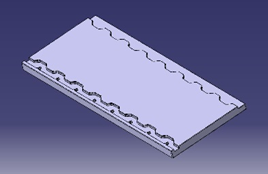

Cutting Jigs: Employed to guide cutting tools in operations like milling.

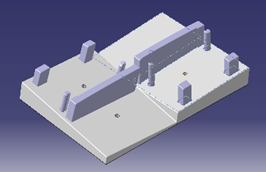

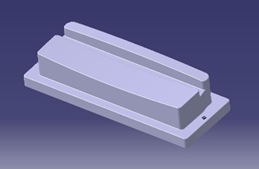

Principles of Jig and Fixture Design

When designing jigs and fixtures, the following points should be considered:

- Positioning Accuracy: Ensuring precise placement of the workpiece or tool in the desired position.

- Ease of Use: The design should allow the operator to use it effortlessly.

- Safety: The design should minimize potential risks for the operator.

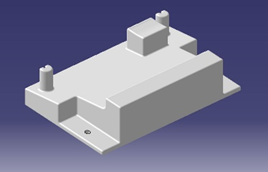

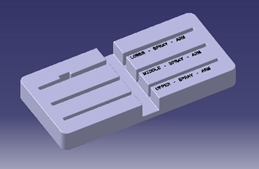

Modern Advancements in Jigs and Fixtures

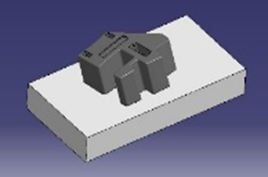

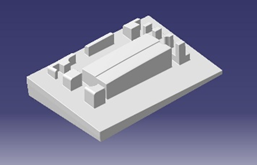

With technological advancements, the use of 3D printing in manufacturing jigs and fixtures has become widespread. This method enables faster and more cost-effective production of these tools, allowing engineers to implement more complex designs.

Optimizing Production with Jigs and Fixtures

The effective use of jigs and fixtures can lead to increased productivity, reduced costs, and improved product quality. These tools significantly enhance the overall efficiency of manufacturing units by minimizing human errors and increasing precision in production processes.

Conclusion

Jigs and fixtures are essential tools in the manufacturing industry that contribute to improving accuracy, speed, and quality in production processes, ultimately enhancing productivity and reducing costs. Considering technological advancements, modern approaches such as 3D printing in jig and fixture design and manufacturing can provide even greater benefits.

Achieve desirable results with minimal costs

Improve production efficiency

Increasing the quality and quantity of production

Consulting in the production of special parts

Customer convenience and non-involvement in processes